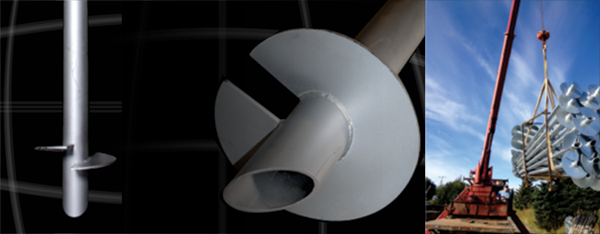

A helical anchor/pile is a segmented deep foundation system with helical bearing plates welded to a central steel shaft. Load is transferred from the shaft to the soil through these bearing plates. Central steel shafts are available in either Type SS (Square Shaft) series or Type RS (Round Shaft) series. The Type SS series are available in 11⁄4" to 21⁄4" square sizes. The Type RS series are available in 27⁄8" to 8" diameter sizes.

Segments or sections are joined with bolted couplings. Installation depth is limited only by soil density and practicality based on economics. A helical bearing plate or helix is one pitch of a screw thread. All helices, regardless of their diameter, have a standard 3" pitch. Being a true helical shape, the helices do not auger into the soil but rather screw into it with minimal soil disturbance. Helical plates are spaced at distances far enough apart that they function independently as individual bearing elements; consequently, the capacity of a particular helix on a helical anchor/pile shaft is not influenced by the helix above or below it.

Lead Section and Extensions

The first section or lead section contains the helical plates. This lead section can consist of a single helix or up to four helices. Additional helices can be added, if required, with the use of helical extensions. Standard helix sizes are available upon request. The helices are arranged on the shaft such that their diameters increase as they get farther from the pilot point. The practical limits on the number of helices per anchor/pile is four to five if placed in a cohesive soil and six if placed in a

cohesionless or granular soil.

Plain extensions are then added in standard lengths of 3, 5, 7 and 10 feet until the lead section penetrates into the bearing strata. Standard helix configurations are provided in the product series tables in this section. Note that lead time will be significantly reduced if a standard helix configuration is selected.

The helix diameter, grade, and thickness along with the shaft series to which an individual helix is connected effect the mechanical strength rating of a helix. A higher mechanical strength rating of an individual helix is possible depending on the combination of these variables.

|